Fully Automatic Brick Making Machinery for Hollow Block QT10-15 Cement Block Making Machine Price Fly Ash Brick Machine for sale

Product Description

QT10-15 Automatic Concrete Block Making Machine Line

QT10-15 Automatic Concrete Block Making Machine Technical Parameters | ||||||||

NO. | Size | Pieces/Mould | Pieces/Hour | Pieces/Shift | ||||

1 | 400*200*200mm | 10 | 1800-2400 | 14400-19200 | ||||

2 | 400*100*200mm | 18 | 3240-4320 | 25900-34560 | ||||

3 | 400*150*200mm | 12 | 2160-2880 | 17280-23040 | ||||

4 | 230*110*70mm | 40 | 7200-9600 | 57600-76800 | ||||

5 | 200*100*60mm | 32 | 5760-7680 | 46080-61440 | ||||

6 | 200*163*60mm | 20 | 3600-4800 | 28800-38400 | ||||

Dimension of Host Machine | 9350*3000*2900mm | |||||||

Weight of Host Machine | 9.8Tons | |||||||

Molding Area | 1096*880mm | |||||||

Water Consumption | 10-15Tons/8Hours | |||||||

Workshop Area | 300m2 | |||||||

Host Machine Power | 67KW | |||||||

Vibration Force | 110KN | |||||||

Mixer Model | JS750 | |||||||

Pallet Size | 1100*900*28mm | |||||||

Voltage | 220/380/415/440V(Customized) | |||||||

Molding Period | 15-20Seconds | |||||||

Vibration Method | Hydraulic+Platform Vibration | |||||||

Vibration Frequency | 2800- 4500Times/Minute | |||||||

Main Features

1. Computer PLC central control system can realize automatic production.

2. Four-bar guiding method and super-long guide bearing are adopted to ensure the precise movement of the up mould.

3. The machine body is made of super-strength steel materials and special welding technology. It is strong and durable in vibration.

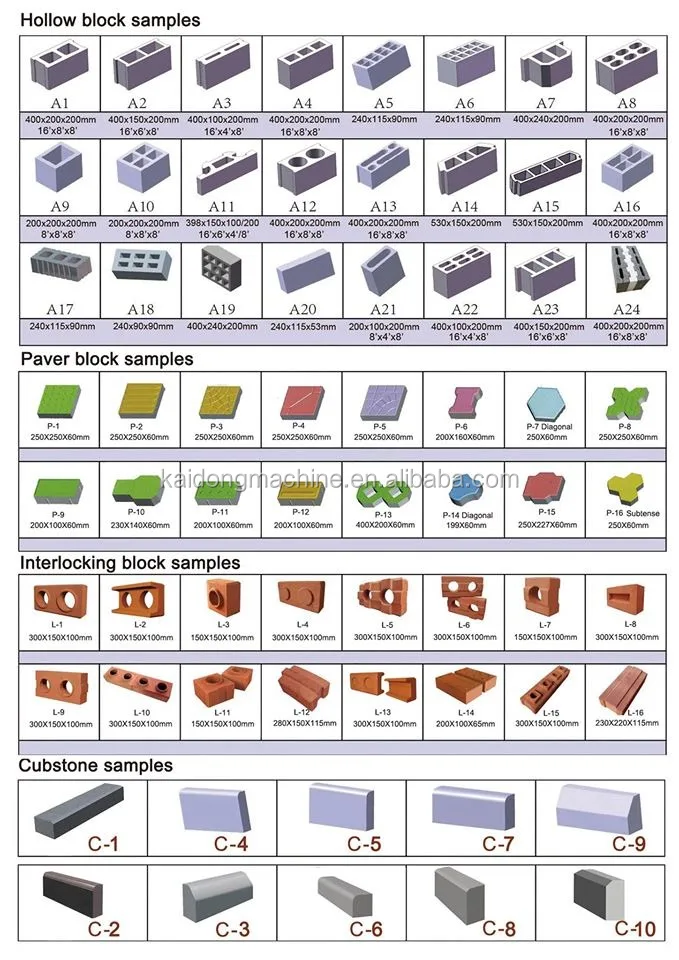

4. It's quick to change mould for producing cement products of different specifications and shapes such as pavement bricks, curbstones, hollow blocks, standard bricks, etc.

5. Seals and some hydraulic components are imported from Europe, the comprehensive performance of the equipment is stable and reliable.

6. The motor adopts the national inspection-free motor (pure copper core), and the hydraulic station adopts the special components for large hydraulic machinery.

7. Mechanical transmission, compact result, convenient maintenance, flexible operation and good reliability.

8. Up and down pressure, strong vibration, especially in the production of heavy bearing high-strength blocks (strength up to 20 MPa).

9. The finished product has high strength, good compactness, precise appearance size, regular shape, no burr and angle drop.

10. Large amount of fly ash, cinder and various waste residues can be used for materials with high efficiency.

11. Small investment, quick results, suitable for different national conditions.

The production capacity depends on this forming machine and it is also the essential part of the whole production line. You can change moulds on this parts to make different shapes of blocks, bricks, colored pavers and curbstones.

The process is controlled by PLC and fitted with remote control device. for PLC control system, we usually use Japan Mitsubishi or Taiwan Brand.

The electricity motor for host machine we use Germany Siemens motor, for other parts, we use CE motor.

About the switches, we will use France Schneider or China CHNT.

Rakes in several rows make sure raw materials fed well-distributed.

Hydraulic components we use Taiwan JiuGang famous brands.

The demolding synchronizer avoids the damage to concrete products.

The vibration system contain two part, one is up-mould vibration box, it is electricity motor to supply the power for up-mould vibration box. And the down mould, there is one big vibration. When the scatter material work is finished, the hydraulic power with the two vibration power will assure the good quality for product.

The mould is processed with carburizing, nitriding, wolfram carbide and quenching which ensures its strength reach to 54~58 HRC and can be used 100 thousand times.

SHANDONG KAIDONG CONSTRUCTION MACHINERY CO.,LTD

Product Categories : Ungrouped