AAC cellular lightweight concrete blocks plant / aac brick machine plant factory /steam-cured aac block production line

Product Description

AAC cellular lightweight concrete blocks plant / aac Brick Machine plant factory

steam-cured aac block production line for sale

(capacity annual : 50000m3 , 100000m3 ,150000m3 ,200000m3 , 300000m3 ...)

sold well in Indonesia , India , Iraq , Burma ,Algeria......

Hello , this is Amy Liu from Shandong Hongfa ,Hope you have a good time in searching our products !

AAC concrete foam brick making machine is also called Autoclaved aerated concrete (AAC), also known as autoclaved cellular concrete (ACC) or autoclaved lightweight concrete (ALC).

Raw material is sand or fly ash ,cement ,lime and ............

AAC blocks advantages

|  |

| |

| |

| |

|

Introduction of aac block aac block production line machines fly ash aac machines sand aac machines

Aerated concrete brick (light brick ) is the light and porous building material. It has light weight keeping temperature cant burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Aerated concrete common conception aac block production line machines fly ash aac machines sand aac machines

Common concrete density is usually 1600-2400kg/m3,but Aerated concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain,main use silicon material (for example:coal ash,sand,stone dust and others ),through making the material small for example sand,they can be used directly if has enough degree of small (for example coal ash.Mixing calcium material lime cement water to a special slop,then add the aluminum dust and the additive.Make the aluminum dust and the special slop have a Chemical reflect.then produce Hydrogen to make the concrete slop to expanding or swell,foam.Next,put them into the curing room to concreting cutting steaming curing,last,there will become the light brick,the porous rate is 70-80%.

Raw material ratio of Aerated autoclaved concrete block

Cement lime fly ash style aerated block raw material proportion

name | unit | Cement lime fly ash |

flash | % | 65-70 |

cement | % | 6-15 |

lime | % | 18-25 |

gypsum | % | 3-5 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.60-0.65 |

Casting system | OC | 36-40 |

Aluminum mixing time | S | 30-40 |

Cement lime Sand style aerated block raw material proportion

Name | Unit | Cement Lime Sand |

Sand | % | 55-65 |

Cement | % | 10-20 |

Lime | % | 20-30 |

Gypsum | % | 2-3 |

Aluminum powder paste(600kg/m3) | 1/10000 | 8 |

Water & material rate |

| 0.65-0.75 |

Casting system | OC | 35-38 |

Aluminum mixing time | S | 30-40 |

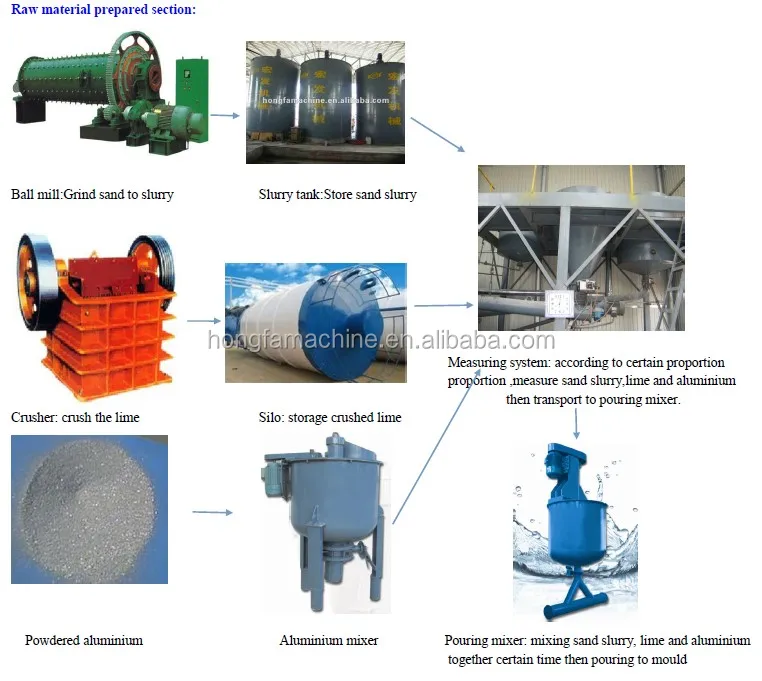

Hongfa aac project main features aac block production line machines fly ash aac machines sand aac 1,Agglomerate lime is firstly crushed by jaw Crusher, and then the granule lime is milled by energy-saving mill.

2,Mixing the fine grinding sands and the waste slurry for the slurry can improves effectively the stability of the slurry.

3,The slurry and powder are weighed by electronic measurement. The measurement and pouring of batching

plant are controlled by central control room.

4,The pouring method adopts fixed point pouring.

5,It chooses the JQF 6.0 step by step cutting machine (Made in China). The maximum cutting size is 6.0×1.2×0.6m and the capacity of the cutting machine is about 400,000 m3 per year. The cutting precision reaches the China advanced level among the same size.

6,The autoclave kettle adopts 2 upward-acting doors to decrease the time of the brick in and out of the autoclave and saves construction areas.

7,Using the integrated process layout, it is conductive to building warm insulate and automatic control of the line. At the same time, it reduces the cost of construction.

8,Using hydraulic transport system instead of travelling crane can improve the stability of the system and save the procedure of application for inspection.

9,The waste on the bottom is cleaned by the hanger with cleaner and then sent to the autoclave kettle for autoclaved maintenance to realize no hard waste for production.

10,Comprehensive utilization of the waste material, waste water, waste gas and rain water helps make full use of the source and reduce emissions.

11,In order to simplify processing and reduce the cost of production, Manual work is needed to clean and oil the molds.

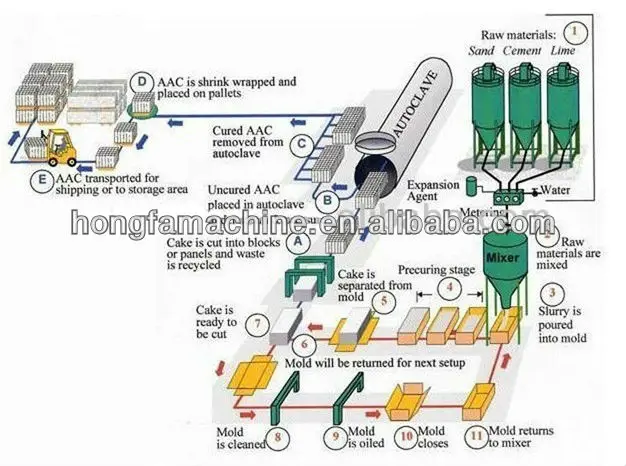

Sketch for aac production line

About Shandong Hongfa aac block production line machines fly ash aac machines sand aac machines

Production line several processes :

- We are the professional manufacturer for aerated autoclaved concrete block making machines with 65% market share in China .

- Strong quality and unbeatable service help us win the customers at home and abroad .

- We have 19 branches around the world and 127 sale departments at home and abroad .

- Your satisfaction is necessary to our success.

- Our goal is to provide you with the best level of customer service, and we welcome your comments and suggestions

Shandong Hongfa Scientific Industrial & Trading Co ., Ltd

Product Categories : Ungrouped