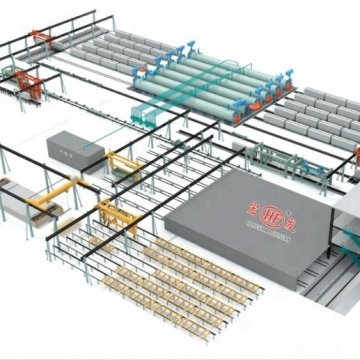

Material dealing process

Put the fly ash or sand into the ball mill to mill via the conveyor belt, after milling, put the slurry into the slurry storage tank by slurry pump.

Aac block production line/autoclaved aerated concrete

Product Description

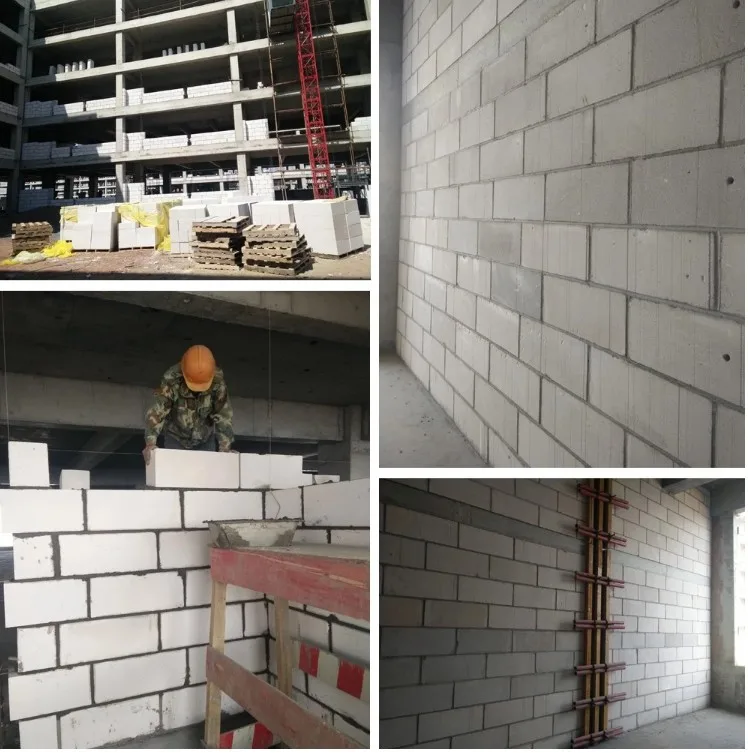

Product Application

AAC (Autoclaved aerated concrete) block Main raw materials of AAC are siliceous material (sand, fly ash and Silicon tailings) and Calcium materials (lime and cement) mixed with foaming agent (aluminum powder). It is the product of light porous silicate through the following processes: batching, mixing, pouring, hardening, cutting, autoclaving and curing etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclaved aerated concrete.

AAC Classification : In general, it can be classified according to the types of raw materials, manufacture process and functions. Based on the shape of AAC products, it can be divided into: AAC blocks and AAC panels. It is a revolutionary material offering an unique combination of high durability and strength, low weight, excellent heat insulation, fire resistant, noise absorption, unprecedented build ability and superior ecological green features. In China, AAC is one of the light wall materials which was popularized and applied at the earliest and the most widely.

Main Features

1. Light weight, can reduce the building's own weight and cost, and help improve the earthquake resistance of buildings

2. Good thermal insulation performance and low thermal conductivity

3. It has processability. It has the same processability as wood. It can be sawed, planed, drilled and nailed, which is conducive to construction and can be operated on site.

4. Strong pressure resistance

5. The aerated block is resistant to high temperature, and the compressive strength of the aerated concrete is slightly increased when the temperature is below 600 °C. When the temperature is around 600 °C, the compressive strength is close to the compressive strength at normal temperature, so The fire performance of aerated concrete for building materials meets national first-class fire protection standards.

packing and delviery

2.The ball mill transport with 40OT or transposrt with 40FR according the size.

3.The autoclave main body transport by car on port,and hoist on deck of ship.

4.Cutting machine usually transport with 40FR.

5.Our package with wooden box,suitable for sea transport..

Product Categories : AAC Production Line

Premium Related Products