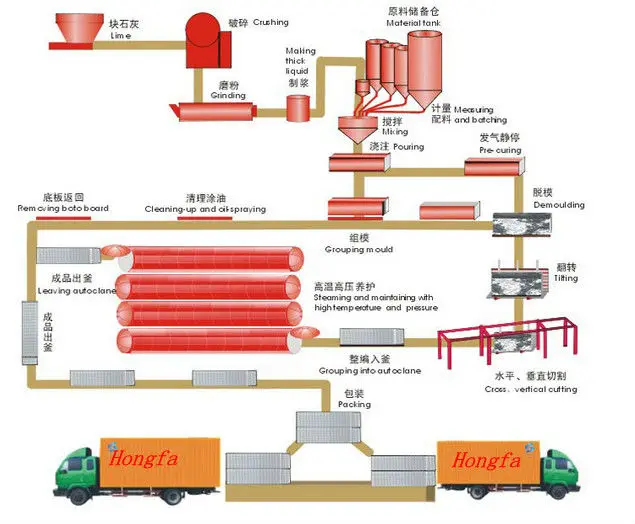

a. First crushed by Jaw Crusher.

b. Second Grinding into powder by Dry Ball Mill.

c. sand also need grinding into powder with wet Ball Mill.

Autoclaved Aerated Concrete (AAC) is a siliceous material (sand, fly ash and silicon tailings such as waste porcelain clay, stone processing waste materials, blast furnace slag, etc.) and calcareous materials (lime, cement) as the main raw material, mixing fat gas agent (aluminum powder), by ingredients, mixing, casting, pre-raising, cutting, autoclave, curing process made of light porous silicate products, because by the hair contains a lot of gas even after the small pores, hence the name of aerated concrete.

AAC block

AAC panel

raw material name | unit | proportion |

fly-ash | % | 65-70 |

cement | % | 6-15 |

lime | % | 18-25 |

gypsum | % | 3-5 |

aluminum powder paste (600kg/m3) | 1/10000 | 8 |

water & material rate | 0.60-0.65 | |

curing room temperature | ℃ | 36-40 |

aluminum mixing time | S | 30-40 |

raw material name | unit | proportion |

sand | % | 55-65 |

cement | % | 10-20 |

lime | % | 20-30 |

gypsum | % | 2-3 |

aluminum powder paste (600kg/m3) | 1/10000 | 8 |

water & material rate | 0.65-0.75 | |

curing room temperature | ℃ | 35-38 |

aluminum mixing time | S | 30-40 |

a. First crushed by Jaw Crusher.

b. Second Grinding into powder by Dry Ball Mill.

c. sand also need grinding into powder with wet Ball Mill.

Gypsum mix with cement , water , Fly-ash into the slur pool

Slurry Pump

Casting mixer with its casting arm, cast all ready concrete into the molds.

Curing room about 35-40 ℃ , next to the Cutting machines (Horizontal & Vertical Cutting machine)

After grouping, into the autoclaves for 8-12 hours.

the side plate will returns automatically to combine into new molds with the Flip sling.

then we finally get the finished AAC Blocks to packed to transfer after separated one layer by one layer.

* Inquiry and consulting support.

* Foundation design drawing.

* View our Factory.

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

TINA Contact info | |

wechat | +86-18769918897 |

whatsapp | +86-18769918897 |

facebook | https://www.facebook.com/tina.hf.54 |

linkedin | https://www.linkedin.com/in/tina-hongfa-machine-hu-992084165/ |

inbox | sales9 at sdhongfa.cn |

Product Categories : AAC Production Line

Premium Related Products