Sales Promotion for 2021! QT12-15 Cement Block Machines Price Fly Ash Brick Making Machine in India

Product Description

Product Description

Introduction

QT12-15 automatic block forming machine adopts a number of domestic leading and international latest technologies, fully reflecting the high content of crystallization technology and advanced design concept of China and Germany's technological wisdom. The humanized design combines 20 years of production experience, and strict process requirements make the machine excellent in quality, stable and reliable in performance, long in use, high in product strength and low in cost, fully reflecting the excellent quality of KAIDONG refined Brick Machine .

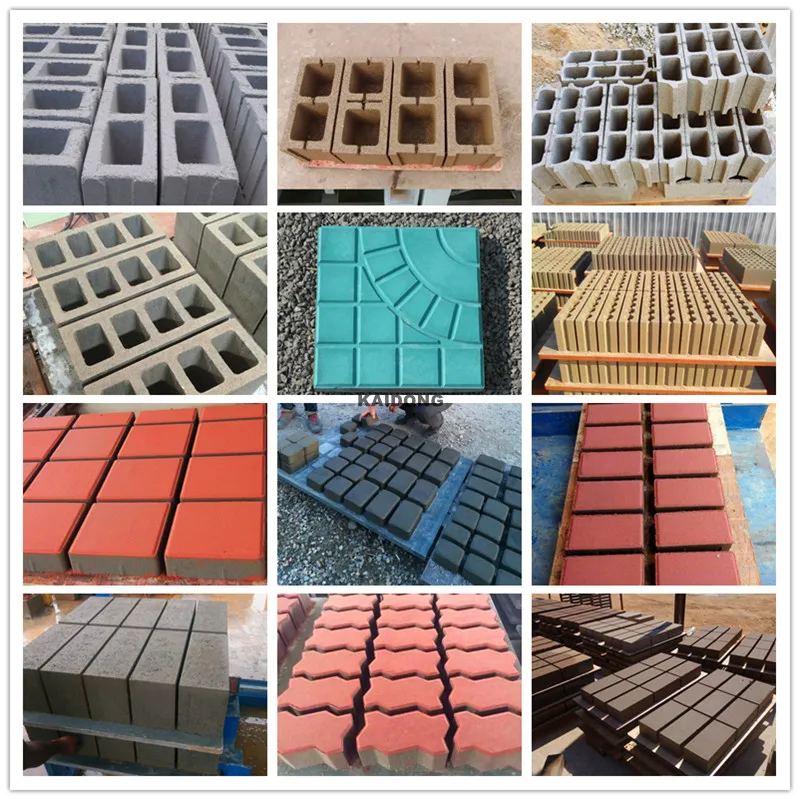

Products Details

1. Vibration system driven by four (Siemens) motors

Siemens motor system is adopted for main machine of brick making machine, and EU standard is adopted for special motor to ensure working stability.

The size of vibration box is increased according to molding area and special brick type. The vibration box with wide area is driven from four directions to ensure the balance of vibration and the effective transmission of vibration force to brick. Compared with vibration system driven by two motors, the vibration efficiency is increased by 30-40%, so as to improve the density and strength of finished brick.

2. Air bag vibration reduction system

It can effectively reduce the vibration noise, quickly eliminate the high-frequency vibration of the whole machine caused by the residual vibration force, so as to prolong the service life of the machine and the mold, and reduce the noise damage and interference to the operators.

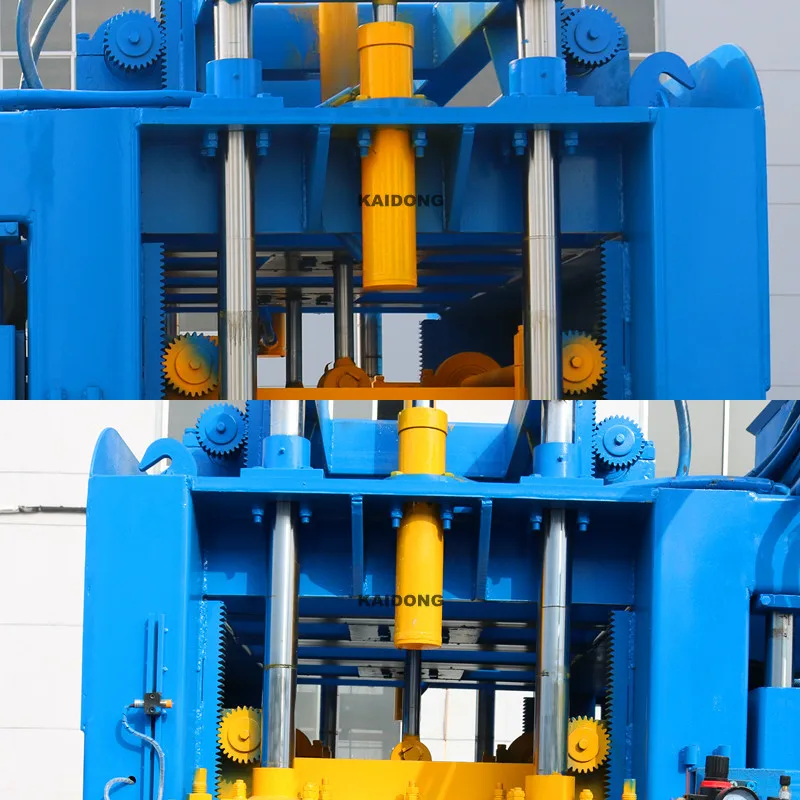

3. High precision gear positioning system for mould

Four synchronous shafts (eight synchronous rack and pinion positioning units) are used for accurate positioning of the upper and lower molds. The gear rack is machined and polished by German and Japanese high-precision machine tools to ensure that the front, rear, left and right sides of the mold are always kept at the same level when the mold body moves up and down, so as to ensure that the height of the cement brick is always consistent. At the same time, the friction coefficient of the upper and lower dies is reduced and the service life of the mould is prolonged.

4. High efficiency distribution system of rear crank arm

Adopting the German design concept, the distribution system adopts double crank arm, double synchronous shaft and 4-cylinder high-efficiency and accurate distribution system to ensure the stability of the distribution system and the efficiency of the feeding speed. Ensure the brick production, reduce the maintenance rate of the machine distribution system.

5. PLC and touch screen are made of Siemens brand in Germany

Ensure the stability and long service life of the program.

6. Calyca brand valve of Taiwan or Yuken brand valve of Japan

Ensure the effective input and output of hydraulic system and long service life.

7. Mould

All the moulds are made of the national standard steel (which has reached the European Union standard). After high-precision cutting and high-temperature carburizing heat treatment (900 ℃ high temperature, 200 ℃ tempering), the die hardness reaches 55-63HRC (ordinary steel has only 25-30HRC hardness).

8. Strong multi axis lengthening and thickening vibration box

According to the machine forming area (mold area), choose 2 to 4 axis thickening and lengthening vibration box to ensure the compactness of finished brick

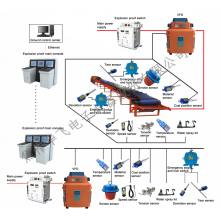

9. Electric box switch system

The main control box adopts French Schneider, German Siemens and or Switzerland ABB switch to ensure working stability and service life.

Specification

QT12-15 Automatic Concrete Block Making Machine Technical Parameters | ||||||||

1 | Dimension of host machine | 3870*2220*2850mm | ||||||

2 | Weight of host machine | 12Tons | ||||||

3 | Molding area | 1220*820mm | ||||||

4 | Water consumption | 15Tons/Day | ||||||

5 | Workshop area | 300㎡ | ||||||

6 | Host machine power | 66KW | ||||||

7 | Vibration force | 100-120KN | ||||||

8 | Pallet size | 1300*900*30/35mm | ||||||

9 | Voltage | 220/380/415/440V(Customized) | ||||||

10 | Molding period | 15-25Seconds | ||||||

11 | Vibration method | Hydraulic+Platform Vibration | ||||||

12 | Vibration frequency | 2800- 5100Times/Minute | ||||||

QT12-15 Block Making Machine

(1)Dimension of host machine: 3870*2220*2850mm (2)Host machine power: 66KW (3)Moulding area: 1220*820mm (4)Vibration force: 100-120KN (5)Moulding period: 15-25Seconds (6)Size of the pallet: 1300*900*30/35mm (7)Weight of the host machine: 12Tons (8)Motor: Siemens (9)PLC: Siemens (10)Hydraulic valve: Taiwan Calyca

(1)JS1000 twin shaft concrete mixer (2)Feeding capacity: 1600L (3)Output capacity: 1000L (4)Production: ≥50m³/Hour (5)Max aggregate size: ≤40/60mm (6)Water supply model: Pump timer (7)Weight: 8800KGs (8)Size: 4000*2280*2650mm

Stacker

(1)Model: KQ-12-S stacker (2)Power: 3KW (3)Mobile double pallet stack (4)Suitable for hollow block and pavers (5)Weight: 1.1Tons

Batching Machine

(1)PL1200 three hoppers (2)Hopper store capacity: 2500L*3 (3)Weight hopper capacity: 1200L (4)Production: 56m³/Hour (5)Batching accuracy: ±2% (6)General dimension: 8300*1950*3000mm (7)Weihgt: 3900KGs

Certifications

Packing & Delivery

Company Profile

KAIDONG MACHINERY

SHANDONG KAIDONG CONSTRUCTION MACHINERY CO.,LTD(SHANDONG KAIQIAN IMPORT & EXPORT CO.,LTD) are professional building materials machinery and equipment research, manufacture and export company. Company business started in 1998, year turnover is more than 50 million USD. The company's main products are concrete block making machine, AAC block machine, concree pole pipe making machine, concrete roof tile machine and mixer. The company passed ISO9001 management system and the European Union CE certification, the products absorb the German mechanical design and manufacturing experience, focus on quality design, high-quality material, exquisite welding and strict inspection process to ensure high-quality equipment and maximize service life. Company products are exported to Southeast Asia, Africa, South America, Eastern Europe, the Middle East, Australia and more than 90 countries and regions.

Company of "integrity first, win-win cooperation", the positive development of quality products, improve the quality of service.

We are not only the machinery products supplier, most important is that we are best program and service supplier according to clients real conditions. Welcome all customers to cooperate with us.

Company of "integrity first, win-win cooperation", the positive development of quality products, improve the quality of service.

We are not only the machinery products supplier, most important is that we are best program and service supplier according to clients real conditions. Welcome all customers to cooperate with us.

Our Customers

If you have interest about our machine, you are welcome to contact: +86 151 6553 9562.

It's available at Whatsapp, Wechat, Messenger, Facebook and other APPs.

E-mail address: joey@kaiqianmachine.com.

Office address: Comprehensive Bonded Zone, Lingong Road No.100, Linyi City, Shandong Province, China

It's available at Whatsapp, Wechat, Messenger, Facebook and other APPs.

E-mail address: joey@kaiqianmachine.com.

Office address: Comprehensive Bonded Zone, Lingong Road No.100, Linyi City, Shandong Province, China

More Products

Product Categories : Automatic Block Making Machine

Premium Related Products

Other Products

Hot Products

Small rock crusher for brick block machineFL2-10 hydraform interlocking compressed earth block machine priceFL5-10 Hydraulic interlocking soil brick machineFactory automatic concrete hollow block brick forms production line for saleHot Sale Africa electric Motor Gasoline Engine Diesel Mini Mobile Cement Mixer with200L,300L,350L,400L,500L Charging CapacityJS750 large capacity automatic self loading concrete mixer for salePLD1200 Ready Mixed Concrete Batching Plantconcrete paver block machine price in indiamobile cement block making machine Germanfull automatic paving stone blocks making machineautomatic introduction interlocking clay block moulds making machineMobile clay interlocking block making machine in nigeriaSemi-automatic block making machine for africaeuro stabilized walking soil cement block making machinefull automatic red soil brick making machinecost of hydraform soil interlocking brick block making machine