Fly ash: A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.

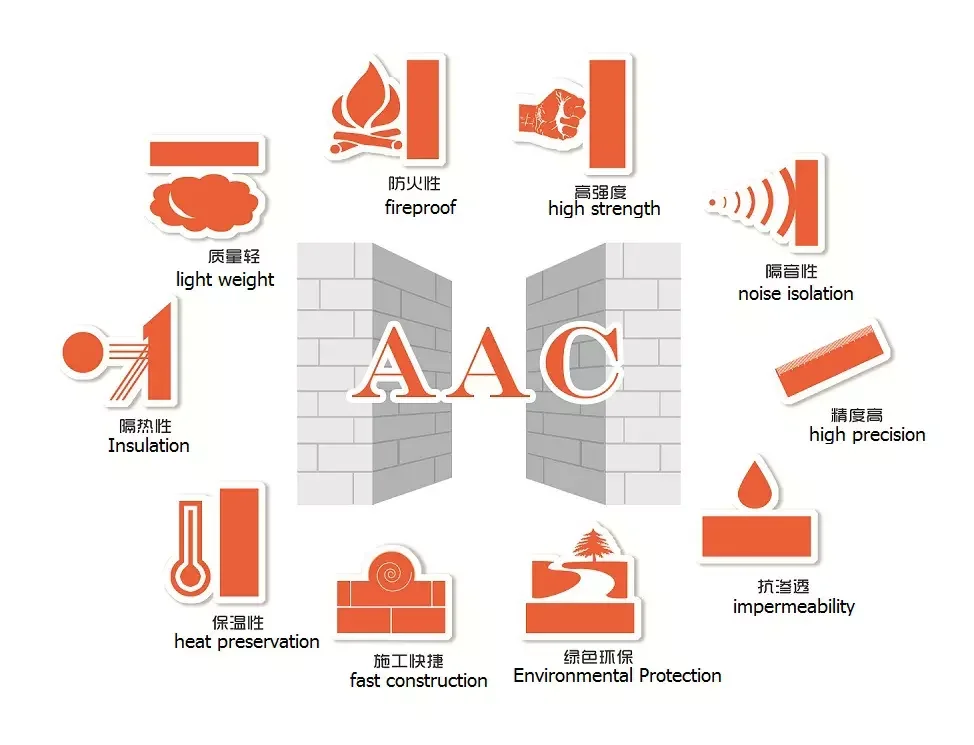

Sand (65-70%): The core raw material of AAC product; the main resource of silica-aluminum components; correspond with JC409-91, the clay should less than 4%.

Cement(8-10%): This Project aims to utilize OPC cement as main binder material. It will give faster strength to the bricks, besides giving improved consistent quality. It also ensures a better cost effectiveness for the same. Using OPC will be a standardized practice. The other prime advantages of using OPC (compared to other binders) is it’s easy availability locally through nationwide Retail Network of Cement Companies.

Gypsum(1-2%): Gypsum is the foaming regulator in AAC which dispels quicklime and postpones slurry’s densification.CaSO4 should be more than 70%.

Aluminum Podwer(0.074%): It is the forming agent type and recommendation for supply depend on raw materials and mix formula:A lot has been said about this raw material in this Project Profile itself. But this Raw material is freely available in Thermal Power plants. There are no taxes on this item whatsoever. Transportation charges are only to be attended by the entrepreneur.