QTM4-30A Egg layer concrete block making machine paving brick machine

Product Description

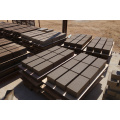

QTM4-30A egg layer Movable Concrete Block Making Machine

Low investment: high efficiency: this machine have several function features, such as low price,reliable performance, easy to operated, stable, more efficient, high output, low power consumption.the brick it produced have high density, high strength, accurate dimensional, good appearance,so it can reduce the customer's investment and production costs and give fast and large benefit.

QTM4-30A Movable Block Making Machine Theoretical Production Capacity | ||||||||

No. | Size (L*W*H) | Pieces/Mould | Pcs/Hour | Pcs/Shift | ||||

1 | 400* 200* 200mm | 4 | 360-480 | 2880- 3840 | ||||

2 | 400* 100* 200mm | 7 | 630-840 | 5040-6720 | ||||

3 | 400* 150* 200mm | 5 | 450-600 | 3600-4800 | ||||

4 | 400*250*200mm | 3 | 270-360 | 2160-2880 | ||||

Main Techinical Parameter | Technical Parameters | |||||||

Dimension of host machine | 1800* 1400* 1100mm | |||||||

Total Weight | 500kg | |||||||

Vibration Method | Hydraulic Pressing+ Vibration Molding | |||||||

Moulding Period | 30-40 Seconds | |||||||

Moving Method | Automatic Moving and Hydraulic Steering | |||||||

Vibration Force | 35KN | |||||||

Mainframe Motor Power | 6.7KW | |||||||

Voltage | 220/380/415/440V(Customized) | |||||||

Pallet | No Need For Pallets | |||||||

Main Features

♦ 1. 40-3A mobile concrete Block Moulding Machine adopts advanced vibration helps raw materials feeding quickly and adequately.

♦ 2. This whole brick plant is made of high quality steel and precision welding.The hydraulic system is featured with high quality

hydraulic components from Taiwan, which has high efficiency, anti fatigue and durability.

♦ 3. Simple and reliable operation,fast production,high capacity,low power consumption(only 1/6 of stationary concrete brick

machine of similar capacity).

♦ 4. No need pallet,this is gonna save lots of investment.

♦ 5. No need to install,able to work after connecting with electricity.

♦ 6. Saving labor: two person are all needed to operate this block maker,one for machine operating and one for mateiral mixing.

Mainframe

Name: QTM4-30A Movable Concrete Block Making Machine

Brand: KAIDONG

Original: China

The production capacity depends on this forming machine and it is also the essential part of the whole production line. You can change moulds on this parts to make different shapes of blocks, bricks, pavers and curbstones.

• The electricity motor for host machine we use Germany Siemens motor, for other parts, we use CE motor.

• About the switches, we will use France Schneider or China CHNT.

• Rakes in several rows make sure raw materials fed well-distributed.

• Hydraulic components we use Taiwan JiuGang famous brands.

• The demolding synchronizer avoids the damage to concrete products.

• The vibration system contain two part, one is up-mould vibration box, it is electricity motor to supply the power for up-mould vibration box. And the down mould, there is one big vibration. When the scatter material work is finished, the hydraulic power with the two vibration power will assure the good quality for product.

• Heavy duty machine structure and wear resistant moulds are processed with carburizing, nitriding, wolfram carbide and quenching which ensures its strength reach to 54~58 HRC and can be used 100 thousand times. Greatly improves the using lifetime of the machine by 50%.

• Use Frequency Conversional Control Technology, which controls the block making:

1. Frequency Conversion Control: guarantees the precise and parallel movement between tamper head and mould, protects the products

from transfiguration; increases the production rate by improving the vibrating efficiency;

2. Controls the instantaneous start and stop of the motors, to protect the motor from over-heating caused by constant working;

3. Power saving: 30%.

• Use Double high-dynamic Proportional/Directional Valves to automatically adjust the oil flow and pressure

1.Buffer the hydraulic cylinder, to protect the cylinder from damage caused by inertia;

2.Guarantee production stability.

• 360° Multi-Shaft Rotating and Compulsory Feeding:

1. Speedy and rotating feeding, with uniform mixing, to make sure that the density and intensity of the products are guaranteed;

2. This uniform feeding is applicable for different kinds of raw materials and moulds.

Mixer

Name: JS500 Horizontal Double Shaft Concrete Mixer

Brand: KAIDONG

Original: China

Before using, connecting to the power source (according to the local power source requirement). Put 8kgs machine oil into gear case. Then, make the machine work for 5 minutes without anything. The next step, put the material (granules and glue) into the container. It takes 5-6 minutes to finish the mixing. After using, please clean the container.

KAIDONG MACHINERY

Our Service

(1) Professional suggestions. recommend the best machine according to the raw material, capacity and the size of brick

(2) Answers to Clients questions on-line

(3) Welcome to visit our factory and production line anytime.

(4) Introduce the company , product categories and production process.

In- Sale:

(1) Update the production scheduling in time

(2) Quality supervision

(3) Product test and acceptance

(4) delivery on time

After-sale:

(1) guide to carry out the plant if needed.

(2)Engineer will help Set up, fix,and operate

(3) offer training to the operator until they are satisfied at clients side.

(4) Skill support the whole using life.

(5) Recall clients regularly ,get feedback in time,keep well communication with each

Product Categories : Moving Block Making Machine

Premium Related Products