Full automatic gypsum board production line in libya

Product Description

Full automatic gypsum board production line in libya

Company brief introduction

Guangxi Hongfa Heavy Machinery Co., Ltd is a leading and professional manufactuere which mainly produce all kinds of AAC block making machines, concrete mixing plants, concrete block making machines, mineral machines etc ,is located at Yiling industry and development zone --- Nanning city, which was honored as " GREEN CITY" by the United Nations.

All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System Certificate, especially AAC block making machine, QT12-15,QT10-15, QT8-15 ,QT6-15 block making machines and SMY8-150 Tile making machine etc were honored as " Guangxi science and technology prize of building Machine Invention", " one of the ten famous brand of brick & tile field in China" praised by Quality Ensure Center of Chinese Light Industrial, " Enterprise that Honor the Contract and keep the Promise", " New high Technology enterprise", "Credible and Reputed Enterprise nationally", " Adhering to grade AAA credit", "Good unit on exporting", " one of the ten credibility enterprise", " Model Unit on Management of Quality" Etc by the state

What is EPS light weight wall panel:

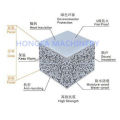

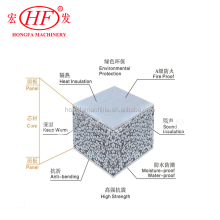

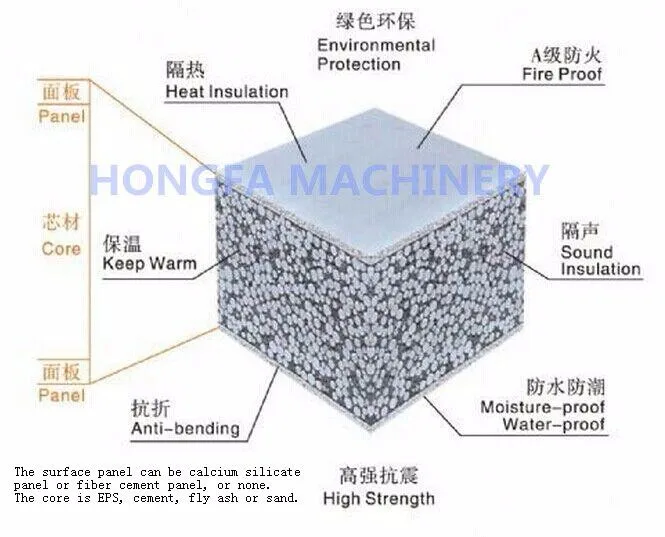

EPS sandwich wall panel is a new type of high-grade light wall panel material with EPS mortar as core material, calcium silicate board as the surface material and properly mixed with fly ash, slag and additives, and the panel formed by the EPS wall panel making machine.

Product size: length 2440mm, width 610mm, thickness 60-180mm (size and thickness can be adjusted). The two surfaces of the new type composite sandwich board are composed of high strength water resistant calcium silicate board with good waterproof properties; good thermal insulation EPS bonding mortar as Core material; The product is of structural function , waterproof and thermal insulation performance, mainly used as building wall partition.

This kind of EPS Sandwich Wall Panel is provided with comprehensive advantage that other wall panel can't compare with: solid, lightweight, thin body, high strength, impact resistance, strong hanging force, heat insulation, sound insulation, fire prevention, waterproof, easy cutting, can be arbitrary slot, without rendering coat, dry decoration, environmental protection. Achieving the purpose of saving energy, improving energy efficiency, Put the construction industry from traditional wet type construction to advanced dry type construction, thus realizing residential parts production industrialization, modernization of technical equipment, intensive production and legal application promotion, construction and equipment integration.

At the same time also can reduce wall occupying space, increase the rate of using residential space, reduce structure load, promote building aseismic ability and safety performance, reduce the comprehensive cost. This product can be widely used in all kinds of high, multi-story building as nonbearing wall, also can be sound insulation, fire partition wall. This product's application is a new breakthrough of the world's wall materials reform, this wall panel have tested by the relevant institutions and its strength, sound insulation, fire resistant, radioactive, water resistance and other performance indexes all reach or over the relevant national standards.

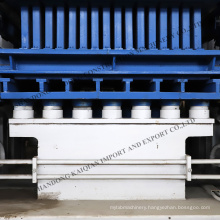

Automatic Vertical forming machine

Manual vertical forming machine

Hotizontal forming machine

Take an EPS Wall Panel production line with annual capacity 200,000m2 for example (700 m2 / day):

(1). An EPS Wall panel production line with annual capacity 200,000m2.

(2).The raw materials cost to produce one square meter of EPS Wall panel ( take 90mm thickness panel for example).

| Materials | Cement | Fly ash | EPS | additive | Silica panel | Water and power | Labor costs | total |

| RMB/m2 | 8 | 3.4 | 6 | 0.5 | 13.4 | 0.52 | 3 | 34.82 |

(3).Costs above calculated based on the below cost table:

| Materials | Cement(ton) | Fly ash (ton) | EPS(ton) | Additive(ton) | Silica panel(m2) | Water | Power(kw) | Worker salary(person/month) |

| Price(RMB) | 330 | 140 | 13000 | 5000 | 6.7 | 0.5 | 0.9 | 3000 |

(4).Other costs

| Cost categories | Management costs | Equipment depreciation | Depreciation of buildings | Maintenance Charge | total |

| RMB/m2 | 1.00 | 0.50 | 0.30 | 0.20 | 2.00 |

(5).Based on the above table, the total production cost is: 37 RMB/m2.

(6).Annual Estimate Benefits

According to China domestic normal selling price:EXW 65RMB/m2

| Annual Output Value(RMB) | Selling expense(RMB) | Annual production cost(RMB) | Annual Profits (RMB) |

| 65×200,000m2 | 13,000,000×5% | 200,000x 37 | 13,000,000-650,000-7,400,000 |

| 13,000,000 | 650,000 | 7,400,000 | 4,950,000 |

How are the land,water,power required to set up an EPS light weight wall panel production line?

Water requirements: to produce 60m2 panel(9 cm thickness as example) required one ton of water. No special requirements for water quality, clean water can be used for production.

Electricity requirement: installed power 30 kw (depending on the capacity).

Requirements on air and steam: Air compressor and boiler.

Land requirements: 1200-2000m2 workshop and 9 meters high (depending on the capacity).

Are your company is the manufacturer or trading company?

We are the direct factory,Hongfa company is the leading and the most influential manufacturer of the EPS light weight wall panel making machine,Concrete Block Making Machine and other wall building materials in China from the 1990s.

Hongfa provides our clients one-stop solution for the EPS sandwich wall panel production line;from us

the clients can share our best quality machines and the most updated technology in the wall panel making industry.

Automatic Vetical type wall panel forming machine

Horizontal Type wall panel forming machine

Simply Vertical Type wall panel forming machine

Eps Lightweight Partition Wall panel

Guangxi Hongfa is the best choice for you

Brand and quality

We are a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine,concrete mixing plant,mixer,concrete block making machine,concrete tile making machine and Concrete Pipe Making Machine etc. with more than 23 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick & Tile field in China" and other honors.

Exhibitions & cooperations

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, Sudan, etc., 96 countries and regions, deeply welcomed by clients from all around the world.

Exhibitions & cooperations

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, Sudan, etc., 96 countries and regions, deeply welcomed by clients from all around the world.

Some suggestion for you

1. What is the brand? ( Now a lot companies embezzle our brand, pls take note our prevention fake-mark.)

2. Does this brand has good reputation and sell well in the market?(we got good reputation and are the biggest supplier in China)

3. What is the materials they used? Maganese steel or A3 steel? (We use Maganese steel which stronger than A3 steel)

4. What is the lifetime of the mold? ( our mold can use 900,000 - 1200,000 times)

5. What is the capacity of this machine? (17280-23040 pcs/8 hours hollow brick)

6.What is the guarantee period? ( We guarantee for one year)

7.The price cover to what equipment?( pls refer to our quotation list)

Free support

Guarantee for one year and after sale service for whole life. To offer free design, free technology support and free machine maintenance trainning.

Free spare parts

We will provide a set of spare parts for free

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Product Categories : EPS light weight wall panel production line

Premium Related Products