Fully automatic EPS Wall Panel Production Line,eps cement sandwich panel production line,automatic horizontal wall panel machine

Product Description

Fully automatic EPS Wall Panel Production Line,eps cement sandwich panel production line,automatic horizontal wall panel machine

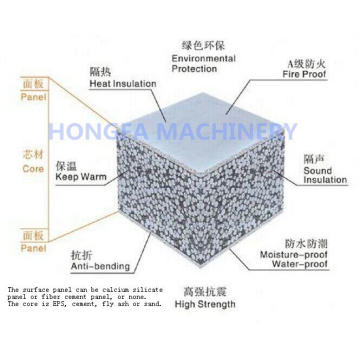

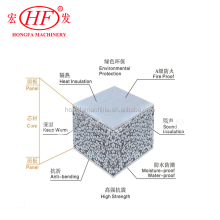

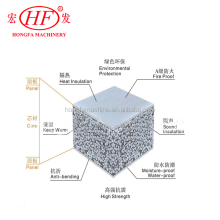

Light weight foam/eps wall panel production line by the programmable control of the electromechanical hydraulic integration of hydraulic molding machine, with a variety of random mold, the production of lightweight composite wall panels. Based on the combination of light high strength, thermal insulation, sound insulation and other properties of the comprehensive requirements to the most advanced with a light high strength, good stability of non-asbestos fiber cement board for the external structure of the panel to take the styrene particles light Concrete for the core material of the new energy-saving solid light composite wall panels. Through the deep research of the system, the composite structure and the splicing structure, the ratio of the panel and the core material and the preparation process parameters are further optimized to improve the mechanical, thermal, sound insulation, fireproofing and durability of the composite strip wall. Is currently the world's most promising new wall materials.

The composition and function of equipment

1, the equipment composition: from the mixing floor, vertical double-panel wall forming machine, mobile flip stripping platform, ferry, hydraulic system, electrical system composed of six parts.

1.1 mixing plant by the cement warehouse, metering system, mixer, stirring support platform and other components, the raw materials for measurement and mixing.

1.2 vertical double-panel wall forming machine from the rack, fixed plate, the middle plate, the activity board, hydraulic system and other components, the mold clamping fixed.

1.3 mobile flip stripping platform by the mobile rack, flip platform, hydraulic system and other parts, the shape of the wall after the demoulding.

1.4 pouring ferry, for the delivery of vertical double-wall forming machine to the mixing tower below the casting and pouring out after the completion of the group set the resting.

1.5 hydraulic system consists of hydraulic stations, pipelines and cylinders and other components, all using well-known brands at home and abroad, its reliable performance, accurate control. The hydraulic station consists of a fuel tank, a motor high pressure pump group, an integrated valve block group, a cooler and an oil return filter. At the same time, the fuel tank is equipped with a temperature measuring and liquid level gauge and a filter plugging device. When the filter is blocked, Filter element.

The machine layout, inspection, installation and preparation

The installation of the machine layout should be based on the production site, product process requirements to determine, in principle, require mixing, ferry pouring, wall forming, stripping flip, maintenance turnover does not interfere with each other, it is recommended to install the base map layout.

Before installation, the installation and operation personnel should carefully read the relevant information, make the installation plan and the necessary preparatory work. According to the basic figure to check the basic size, in which the level of each part of the plane should meet the requirements of the drawings, the base surface should be used cement pouring.

Note: The embedded parts and guide rail position to be accurate, solid, the basis to meet the design requirements to achieve the required installation strength.

Production process

The different requirements of the raw materials required to measure and then placed in the mixer mixing, vertical double open wall forming machine equipped with a good mold, ferry transport vertical double open wall forming machine along the guide to move to the bottom of the mixing floor for grouting, grouting Complete the wall forming machine to rest. After the hardening of the wallboard, the vertical double-wall forming machine is started to start on both sides. The mold is turned to the two sides of the molding machine, the product is stripped, the platform is rotated 90 degrees and the forklift moves to the rear of the turning platform The wall will be forked, thus completing a working cycle.

Technical Parameters

1, hydraulic system rated pressure: 20Mpa

2, voltage: 380V

3, the production specifications:

Length: 2440 ~ 3000mm

Width: 610 mm

Board thickness: 60 ~ 150 mm

Raw Materials

foam(eps)crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes.

Shandong Hongfa Machinery Co., Ltd is a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine, concrete mixing plant, mixer, Concrete Block Making Machine, concrete tile making machine and Concrete Pipe Making Machine with more than 20 years experience and being the biggest manufacturer in China at present. All the products are conformity with the standard of the state, and gets the ISO9001-2008 Quality System Certificate, also honored as 'One of the Top Ten Famous Brands of Bricks & Tile Field in China' and other honors.

Shandong Hongfa Machinery has won many honors through outstanding products and advanced technology and we always see product quality as life and customers as god. We has set up good service philodophy: timely repair the equipment when it breaks down, provide project design and production flow designing for the customers, formulate the equipment purchase plan for the customers, provide high-quality products,provide considerate customer training, timely and effectively repair the fault of the equipment and test and sovle the difficult processing problems for the customers.

Pre-sale service support:

According to each customer's demand and budget, we offer you the professional solution, process flow design and production equipment. More importantly, we welcome every customer to visit our factory and working machine in the site before placing the order. We will arrange cars, hotels and translators for the visiting customers.

During-sale service support:

Assist clients to finish the factory planning. Before delivery equipment to customer s, complete debugging and checking. Provide a full instruction Manual for the whole system. Provide technical guidance for the installation and use of the unit, including installation advice and electrical connection. Provide unit debugging and training for the operation of the machine on the working site and coordiante the customers with check and acceptance of the unit.

After-sale service support:

Send technicians to installation site for the guidance, equipment adjustment and training. Provide high-quality spare parts thoughout the year, and the maintenance technicians are always ready to provide technical help.

Trade shows

Delivery2

Contacts

Manager:Ken Zhang

Cel:+86-18315759901 (whatsapp)

Product Categories : EPS light weight wall panel production line

Premium Related Products