aac brick block production line machinery/concrete aac pannle prices/aac block production in myanmar

Product Description

Product Description

aac brick block production line machinery/concrete aac pannle prices/aac block production in myanmar

Areated concrete brick (light brick ) is the light and porous buidling material. It has light weight keeping temperature can't burn and other advantages.it can be made into many kinds of bricks(for example:600×200×100,80×80×180,240×115×53,600×200×125),they could be used industry building and common building.they are more and more popular in the world.in the future,they will replace the Clay brick completely.

Areated concrete common conception

Common concrete density is usually 1600-2400kg/m3,but Areated concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain,main use silicon material (for example:coal ash,sand,stone dust and others ),through making the material small for example

sand,they can be used directly if has enough degree of small (for example coal ash.Mixing calcium material lime cement water to a special slop,then add the aluminum dust and the additive.Make the aluminum dust and the special slop have a Chemical reflect.then

produce Hydrogen to make the concrete slop to expanding or swell,foam.Next,put them into the curing room to concreting cutting steaming curing,last,there will bacome the light brick,the porous rate is 70-80%.

Common concrete density is usually 1600-2400kg/m3,but Areated concrete are 500kg/m3,600kg/m3,700kg/m3.It has not the big grain,main use silicon material (for example:coal ash,sand,stone dust and others ),through making the material small for example

sand,they can be used directly if has enough degree of small (for example coal ash.Mixing calcium material lime cement water to a special slop,then add the aluminum dust and the additive.Make the aluminum dust and the special slop have a Chemical reflect.then

produce Hydrogen to make the concrete slop to expanding or swell,foam.Next,put them into the curing room to concreting cutting steaming curing,last,there will bacome the light brick,the porous rate is 70-80%.

Advantages

1)light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

2)keeping temperature

It has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

1)light weight

Areated concrete density is usually 400-700kg/m3,(according the market in produce ),same as 1/3 of clay brick and 1/5 common concrete.So use the Light brick can reduce the weight of the build more,and also reduce the beam of roof and pillar press best.then you can see,it can save the material and cost,it also fighting shaking.

2)keeping temperature

It has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

Our local has the working site, if you are interested, welcome to add Nena wechat/whats app: 0086-13256553670

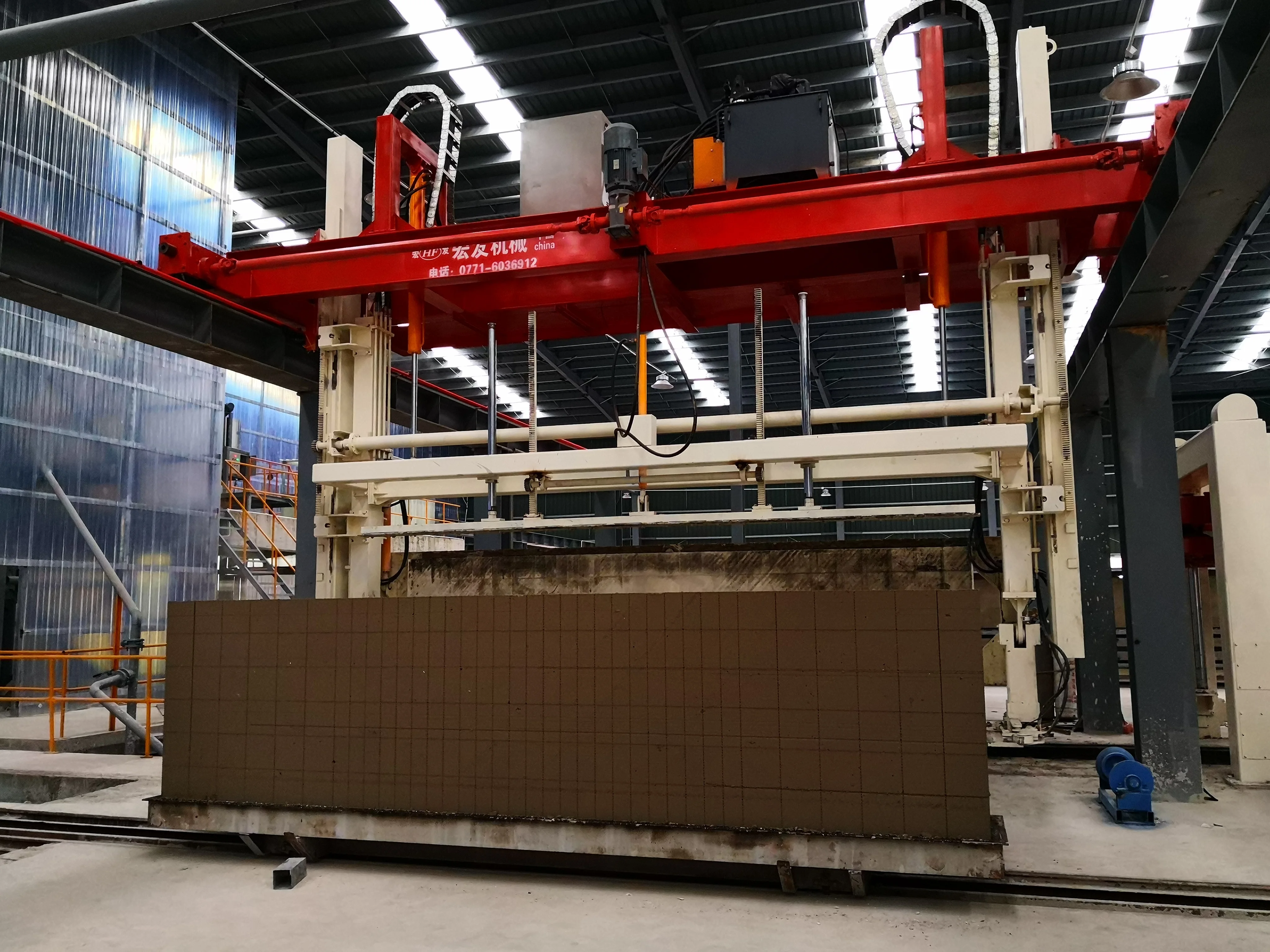

Detailed Images

Detailed Product Description

1)Foam block machine,best offer with most competitive price ,quality guarantee machine, any size block widely used for high buildings,walls, etc many many infrastructure projects.

2)We are the top leader in China on manufacturing the Autoclaved Aerated Concrete Line(AAC) with 65% market share. We have exported our lines to different countries -- Russia, Thailand, Ukraine, Middle East and so on.

3)We can supply our customer for designning, production, installation, commissioning, training and good after-sale service.

4)Capacity: from 50000 cubic meter to 300,000 cubic meters per year.

5)Equipments: stocking raw materials, mixing, molding, forming, cutting, evaporating and curing, crane cramp, transporting etc.

1)Foam block machine,best offer with most competitive price ,quality guarantee machine, any size block widely used for high buildings,walls, etc many many infrastructure projects.

2)We are the top leader in China on manufacturing the Autoclaved Aerated Concrete Line(AAC) with 65% market share. We have exported our lines to different countries -- Russia, Thailand, Ukraine, Middle East and so on.

3)We can supply our customer for designning, production, installation, commissioning, training and good after-sale service.

4)Capacity: from 50000 cubic meter to 300,000 cubic meters per year.

5)Equipments: stocking raw materials, mixing, molding, forming, cutting, evaporating and curing, crane cramp, transporting etc.

AAC Production Line/Autoclaved Aerated Concrete Production Line

1)Product weight is according to 600kg/m3 to control.

2)annual capacity 300,000M3.

3)set raw material proportion: cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4)water and material rate 0.631

5)one mould product 2.88M3

6)Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7)casting slurry temperature 38-42 degree

8)body quiet stop. Time is 1.5-2.5hours, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9)Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours.

10) Cement lime fly ash style aerated block raw material proportion

1)Product weight is according to 600kg/m3 to control.

2)annual capacity 300,000M3.

3)set raw material proportion: cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4)water and material rate 0.631

5)one mould product 2.88M3

6)Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7)casting slurry temperature 38-42 degree

8)body quiet stop. Time is 1.5-2.5hours, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9)Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours.

10) Cement lime fly ash style aerated block raw material proportion

if you are interested, welcome to add Nena wechat/whats app: 0086-13256553670, let me send you pricelist

name | unit | proportion | ||||

flash | % | 65-70 | ||||

cement | % | 6-15 | ||||

lime | % | 18-25 | ||||

gypsum | % | 3-5 | ||||

Aluminum powder paste(600kg/m3) | 1/10000 | 8 | ||||

Water & material rate | 0.60-0.65 | |||||

Casting system | OC | 36-40 | ||||

Aluminum mixing time | S | 30-40 | ||||

Cement lime Sand style aerated block raw material proportion | ||||||||

Name | Unit | proportion | ||||||

Sand | % | 55-65 | ||||||

Cement | % | 10-20 | ||||||

Lime | % | 20-30 | ||||||

Gypsum | % | 2-3 | ||||||

Aluminum powder paste(600kg/m3) | 1/10000 | 8 | ||||||

Water & material rate | 0.65-0.75 | |||||||

Casting system | OC | 35-38 | ||||||

Aluminum mixing time | S | 30-40 | ||||||

Reference: cement is 42.5 Portland or 42.5 common cement

Aluminum power paste calculate to use according to 600kg/m3

Remark: the accurate batching rate is adjustable according to the raw material locally

Aluminum power paste calculate to use according to 600kg/m3

Remark: the accurate batching rate is adjustable according to the raw material locally

Related Products

if you are interested, welcome to add Nena wechat/whats app: 0086-13256553670, let me send you pricelist

Company Introduction

Certifications

Our Services

Pre-sale Service 1.We have full stock, and can deliver within short time.Many styles for your choices. 2.Good Quality + Factory Price + Quick Response + Reliable Service, is what we are trying best to offer you. 3.All of our products are produce by our professional workman and we have our high-work-effect foreign trade team, you can totally believe our service. After-sale Service 1.We are very glad that customer give us some suggestion for price and products. 2.If any question, please contact with us freely by E-mail or Telephone.

Packing&Shipping

FAQ

1.Q:What is the material of the brick? A: Cement,sand,stone.fly ash,building waste and so on. 2.Q:What kind of the brick that the brick making machine can produce? A: All kinds of the hollow block and paving brick. You can customize the type of brick. 3.Q:what is the driving power of the Hollow Block Making Machine? A: Electricity and Diesel Engine. 4. Q: Are you a manufacturer of a trading company? A:We are the biggest building materials machinery manufacturers, with strong technical force, reliable product quality, which merge science,industry and trade together in one.Welcome to our factory at any time. 5. Q: How can I pick up a suitable machine ? A: Only clarify your required output per day or per shift (8 hours) as well as your budget, then we can recommend suitable machine with very competitive price. 6. Q: How about the installation ? A: We support Overseas Installation for all our medium / big machines, small machines you will gain online video technical support (Trading company may not support). 7.Q: What kind of blocks can be produced by this plant? A: You can get blocks with different sizes by changing the position of cutting wires. 8. Q: Can you assure the quality? A: Yes, we can. Our equipment will be carefully tested before shipping, and can be used over 10 years. If you worry about that, we can make the translation via Trade Assurance Order on Alibaba. 9. Q: How can I get this plant? A: You can visit our factory at first, and if you want to buy, we can transport the equipment to you by sea after we get the payments.

Any one interest you, welcome to add Nena wechat/whats app: 0086-13256553670, let me send you details.

Product Categories : Concrete Batching Plant > Concrete Batching Plant

Premium Related Products

Other Products

Hot Products

Small rock crusher for brick block machineFL2-10 hydraform interlocking compressed earth block machine priceFL5-10 Hydraulic interlocking soil brick machineFactory automatic concrete hollow block brick forms production line for saleHot Sale Africa electric Motor Gasoline Engine Diesel Mini Mobile Cement Mixer with200L,300L,350L,400L,500L Charging CapacityJS750 large capacity automatic self loading concrete mixer for salePLD1200 Ready Mixed Concrete Batching Plantconcrete paver block machine price in indiamobile cement block making machine Germanfull automatic paving stone blocks making machineautomatic introduction interlocking clay block moulds making machineMobile clay interlocking block making machine in nigeriaSemi-automatic block making machine for africaeuro stabilized walking soil cement block making machinefull automatic red soil brick making machinecost of hydraform soil interlocking brick block making machine